Packaging and Printing

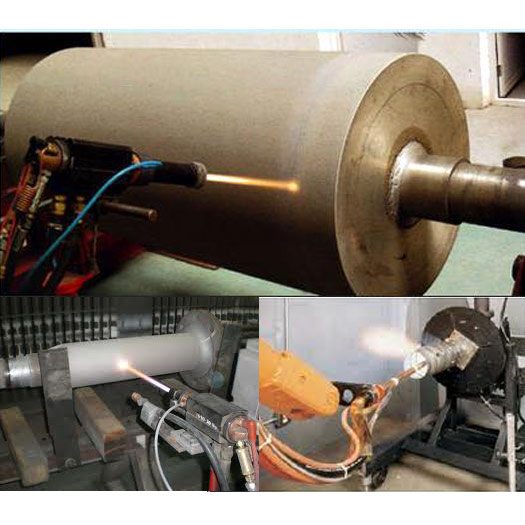

Spray area: Corrugated corrugated board production equipment is the most important part

Work Status: intermetallic wear

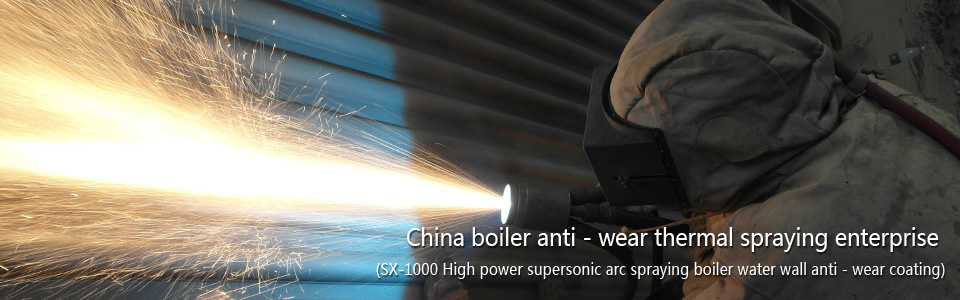

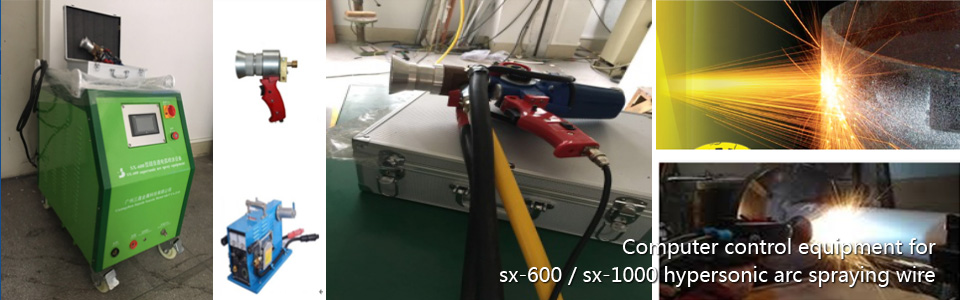

Solutions: Solutions: Arc Spray / HVOF Spray

coating materials: sprayed tungsten carbide

use effect: Corrugated spraying equipment using supersonic obtain high wear-resistant coating of tungsten carbide. hardness up HV1200 more so than ordinary rolls Corrugated improve the life of four to five times, but also can reduce scrap, reduce the amount of glue, cardboard quality assurance, and improve productivity

Applications: for packaging, printing industry Corrugated corrugated board production equipment is the most important part, it is generally used 48CrMo steel, hardened or nitrided by IF, the hardness in HRC55 or more generally. Corrugated single machine is the key part of ordinary Corrugated tooth height, the top circle changes, unstable cardboard quality gap core paper and glue roller wear with Corrugated middle enlarged, while the top of the circle after the wear increases have led to excessive amount of glue, making cardboard soft and pliable.

>> Previous: Screw surface

>> Next: Mechanical components