Company Profile and Benefits

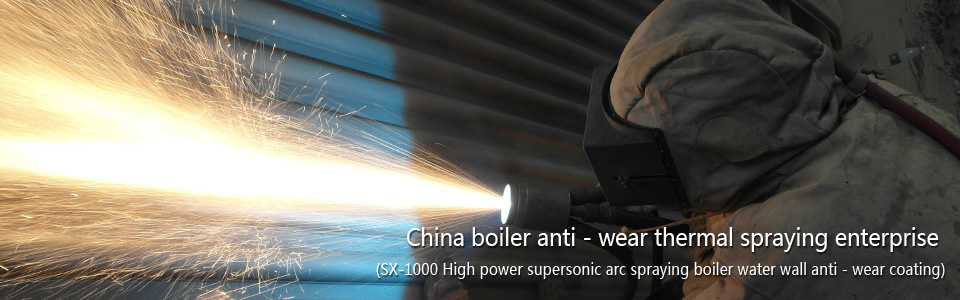

GuangZhou SANXIN Metal S&T Co., LTD. was established in 1989 from Kai Nonferrous Metal Research Institute's experimental base. Sanxin million and is in the original source of thermal spraying plants established on the basis of high-tech enterprise, specializing in metal surface treatment and cold thermal spraying Thermal spray coating and cold spray technology research, development, and application of excellence, the introduction of foreign advanced surface engineering technologies and processes, using plasma, HVOF, arc and other high-speed devices can be widely used in electricity, water, wind, nuclear power generation, shipbuilding, ship, metallurgy, mining, machinery, electronics, light industry, petroleum, chemical, steel, printing, paper, cement, chemical, textile, large bridges, steel construction, railway, aviation, aerospace, automotive, valves pump target ball mold and other industries, is a national focus on promoting technology companies have national level construction qualification thermal spray engineering, thermal spraying China Surface Engineering Professional Committee Member, Chinese Thermal Spray cooperative group members. term commitment to the power plant boiler wear, anti- corrosion, thermal spraying and cold spraying and power plant flue gas desulfurization scene of major projects, particularly in the field of Chinese boiler four integrated application development and foreign power can provide high-quality coatings.

Business:

Business:

Thermal Spray a large area on-site construction works,

thermal spray equipment wholesale sales and manufacturing exports,

turnkey production lines and equipment for coating

1. Professional large construction site thermal spray coatings

power plant boiler four wear resist supersonic arc thermal spraying nickel base, chromium-based, solid core wire cored wire, stainless steel coating, thermal sprayed aluminum thermal spray zinc, sand-blasting, spray, plasma spray high-performance ceramic coatings, aluminum oxide, chromium oxide, titanium oxide, zirconium oxide, molybdenum carbide, cermet HVOF thermal spray coatings, tungsten, nickel, chromium carbide, chromium, nickel-chromium alloy. dedicated long-term anti-corrosion coating layer. thermal spraying cold using spray technology.

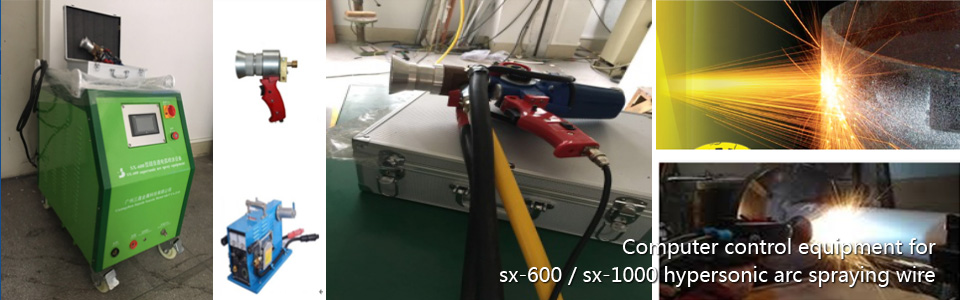

2. thermal spray equipment manufacturing sales and exports

advanced high sonic arc spraying equipment, gas HVOF spraying equipment, plasma spraying equipment

3. turnkey production lines and equipment for coating

A Thermal spray coating applications in the national economy:

advanced supersonic arc, HVOF HVOF, plasma spray coating corrosion wear thermal processing, thermal spray zinc spray aluminum, such as spray coating process

• Energy thermal power, water power, wind power, nuclear power, mechanical manufacturing, aerospace, mining and metallurgy, shipbuilding, ships, electronics, light industry, petrochemical, municipal building, construction, steel, printing, paper, printing & dyeing, cement, chemical, textile , large bridges, large steel, railways, thermal spray zinc spray aluminum, automobiles and other machinery and equipment industry thermal spray processing grinding mirror polishing, restoring dimensions repair corrosion wear protective coating layer.

B large area thermal spray layer construction professionals electric power industry application

Power Systems:

1. thermal power plants, steel mills, cement plants, and other large industrial coal-fired / CFB boiler and pulverized fuel boilers “ four ” that: Water-cooled wall tubes, superheater tubes, reheater tubes, economizer / fuel tube coating layer.

2. fan impeller thermal power plants, power plants, people sprayed layer fan blades.

3. thermal power plant steam turbine cylinder head sealing surface thermal spray repair

4. water gate hydropower, buck station power distribution equipment, high-voltage transmission tower, etc. sprayed zinc coating sprayed aluminum and its alloys long-lasting anti-corrosion coating.

5. overcurrent hydropower turbine parts such as: runner, guide the water leaves, bottom ring, cover, tail pipes and other anti-cavitation brush spray coating.

6. diesel generator crankshaft wear after spraying repair.

7. wind power base coating layer.

Function abrasive wear coat erosion resistant coating erosion-resistant coating corrosion resistant coating

coating materials: cermet, nickel-based alloys, chromium-based alloys, oxidation ceramic coating material, 45CT high chromium nickel-iron-chromium-aluminum coating. cored wire solid core wire, ceramic powder.

spraying method: hypersonic flame spraying, high velocity arc spraying, plasma spraying.

Application Example: Boilers “ four ”(water wall tubes, superheater organs, preheater tubes and provincial gas tank), boiler exhaust fan blades, coal grinding system sealing rings, hydraulic piston, turbine leaves, leaf hydraulic conductivity, sea water pump impellers, turbine runner, fan impeller.

Partners: Huaneng Power Datang Power GD CLP Investment Huadian Power COFCO Power Textile Paper Power Cement Power industrial power and other industries

>> Previous: Contact

>> Next: R & D Center