Cold Spray Technology

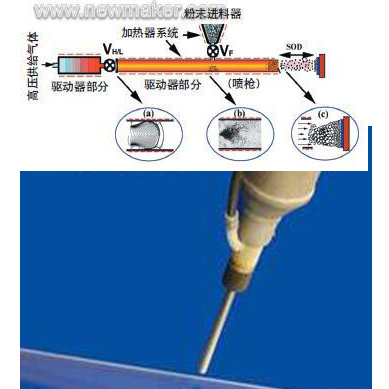

Cold Spray Technology: stands for the power of cold air spray technology, high-pressure gas pipe produced by scaling supersonic flow, the particles from the gas stream is fed axially through accelerated to crash completely solid substrate to form a coating.

Cold Spray Technology Features: is mainly used with a plastic coating material, such as pure metals, metal alloys, plastics and composites, especially due to its low heat, the advantage of substantially non-oxidizing, suitable for temperature sensitive materials (nm, amorphous, etc.), sensitive to oxidation (cu, ti, etc.) and sensitive (carbide composite material) of a phase change material of low stress coatings, and the compressive stress, thicker coatings favor deposition , and the powder can be recycled. principal factors

affect the flight speed of the particles have a geometric shape following: Zoom tube, the pressure of the working gas and preheat temperature

size and density of particles, the working gas is generally compressed air, the gas pressure is generally 1.5-3.5 mpa, the gas pressure, the greater the particle velocity. preheating temperature is usually 100 ℃-600℃, the higher the preheating temperature, the greater the speed of the particles obtained.

>> Previous: Nuclear power motor revolution

>> Next: Ships military ship industry