Cold Spray Technology

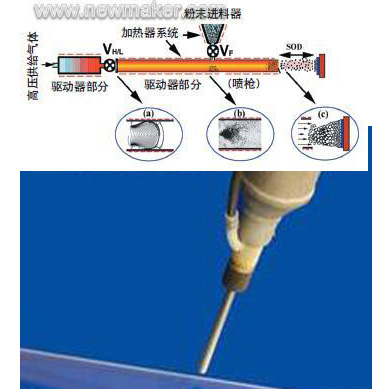

Cold Spray Technology: stands for the power of cold air spray technology, high-pressure gas pipe produced by scaling supersonic flow, the particles from the gas stream is fed axially through accelerated to crash completely solid substrate to form a coating.

Cold Spray Technology Features: is mainly used with a plastic coating material, such as pure metals, metal alloys, plastics and composites, especially due to its low heat, the advantage of substantially non-oxidizing, suitable for temperature sensitive materials (nm, amorphous, etc.), sensitive to oxidation (cu, ti, etc.) and the phase-sensitive variable (carbide composites) material of low stress coatings, and a compressive stress, favor deposition thicker coatings, and powder can be recycled.

The main factors that affect the flight particle velocity has the following: Scale tube geometry, the pressure of the working gas and the preheating temperature

Particle The size and density of the working gas is generally compressed air, the gas pressure is generally 1.5-3.5 mpa, the higher the gas pressure, the greater the particle velocity. preheating temperature is usually 100 ℃-600℃, the higher the preheating temperature, the particles obtained the greater the speed.

>> Previous: Nuclear power motor revolution

>> Next: Coating target