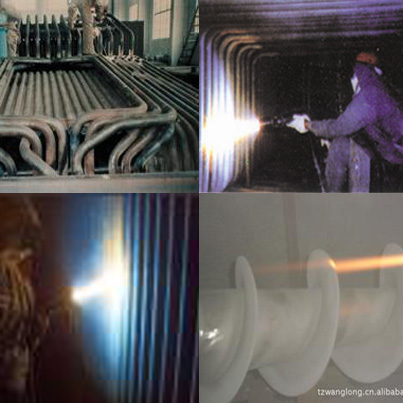

Pulverized coal boiler economizer (or oil) tube four spray corrosion resistant

Spray area: Power Plant Boiler four thermal spray CFB circulating fluidized bed boiler pulverized coal boiler economizer (or oil) tube wear and corrosion coatings ignition belt

Work status: High-speed abrasive wear of materials / sulfide / high temperature corrosion

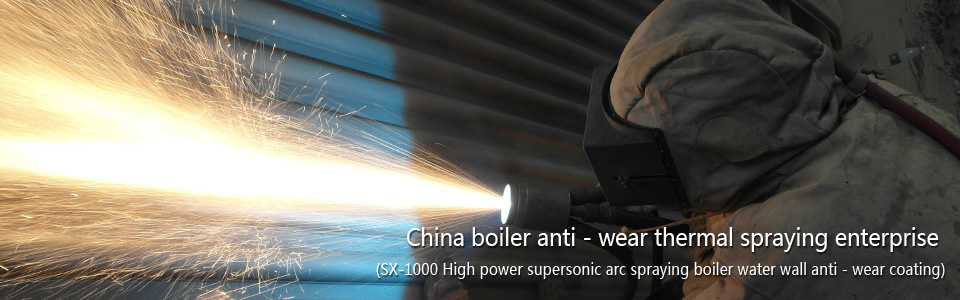

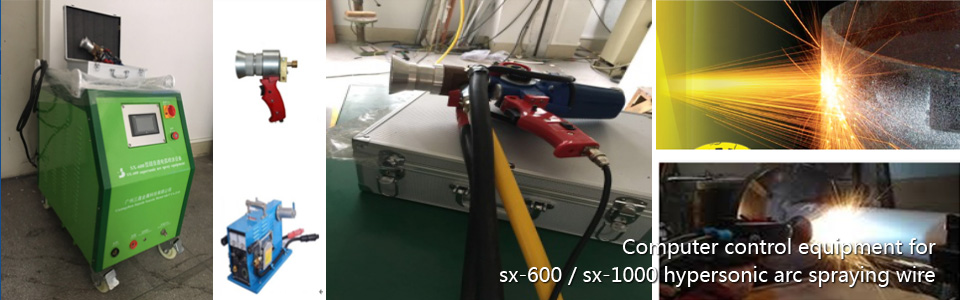

Solutions: High Velocity Arc Spraying / supersonic spray / Cold Spray

coating materials: Resistance high-temperature metal-ceramic corrosion resistant materials

use effect: to improve the corrosion wear life 3 - 8 times

Applications: thermal power plant circulating fluidized bed boiler and coal boilers four pipe (water wall, superheater, reheater, economizer, or fuel economy) thermal spray corrosion, erosion and wear resistance, high temperature materials, can effectively extend the boiler maintenance cycle, but also be able to combine the power plant turbine head surface leakage fault repair thermal spray corrosion resistant material, and exhaust fan, suction fan impeller, wear coal grinding system to strengthen the repair, turbine hydropower overcurrent bit, gates shell, drainage vacuum tubes, wheels, guide vane ring, cover and other thermal spray cavitation erosion protection, anti-wear diesel generator crankshaft repair, wind turbine base spray

>> Previous: CFB reheat economizer wear and corrosion coating