Application of coating materials

Thermal spray materials

currently has achieved practical application of coating materials for industrial production of metals, alloys and ceramics, mainly in powder, wire, bar state use, which accounts for spraying powder coating materials of the total amount of 70% more Used as coating materials are:

1, the thermal spraying powder

pure metal powder: W, mo, al, cu, ni, ti, ta, nb, etc.

alloy powder: Al-Ni, Ni-Cr, Ti-Ni, Ni-Cr-Al, Co-Cr-W, MCrAlY(M=Co, Ni, Fe) , co base, ni base, fe-based self-fluxing etc.

oxide ceramic powders: Al2O3, zrO2, cr2O3, tiO2 etc.

carbide powder: WC, tiC, cr3C2 etc.

Metal ceramic powder:WC-Co, Cr3C2- NiCr etc.

plastic powder: nylon, polyethylene, polyphenylene sulfide

2, with thermal spray wire

Al, Cu, Zn, Sn, Al- Zn alloy, babbitt, stainless steel, ni - Al wire, etc.

3, thermal spraying bar

Al2O3, zrO2, cr2O3 etc.

coating functions and applications

1, anti-wear coating

wear is caused by damage to the equipment industry One of the main reasons, may have worn working conditions, including fretting, sliding, impact, abrasion, erosion, etc. should be hard wear-resistant coating, and has heat and chemical resistant properties. fe, ni, co-based self-fluxing and WC - Co and Cr3C2 - NiCr and other metal-ceramic and Al2O3, cr2O3 other ceramic materials with these properties. using coating technology to improve the wear resistance of the surface is widely used, such as piston rings gear synchronizer ring sprayed Mo coatings, textile machinery rollers, guide wire hooks and other parts spraying wear-resistant fiber Al2O3, al2O3 — TiO2 ceramic coating, spray pump and valve sealing surface Cr2O3, WC - Co and other wear-resistant coatings, high-powered trucks and large mill crank, exhaust fan shaft and other Fe-based alloy material to repair the wear and abrasion strengthen etc.

2, anti-corrosion coating

Long-term exposure Outdoor air (Marine, industrial and urban atmosphere) and different media (water, oil and other solvents and water) environments of large steel structures, such as power transmission tower, steel bridges, offshore drilling platforms, coal derrick and a variety of chemical containers, such as tanks, etc., are subject to different degrees of environmental oxidation and erosion. using Al, zn, al - Zn alloy and stainless steel coating for protection, you can get up to 20 years or more long-term protective effect. Some components by gas erosion and chemical corrosion protection may be specific conditions (such as the medium, concentration, temperature, pressure, etc.) to select a suitable metal, alloy, ceramics and plastics coating material according to

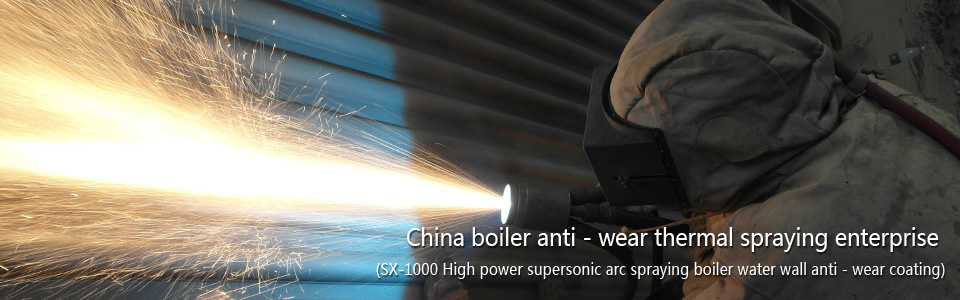

3, high temperature oxidation and corrosion resistant coating

For some exposed to high temperature corrosive gas components subjected to high temperatures, corrosive gases and air scour role seriously affected the life and safety of the equipment running. resistance to high temperature oxidation and high temperature corrosion In addition to the material must be resistant to high temperature oxidation and corrosion, but also must have a coefficient of thermal expansion similar to the material and the substrate, temperature cycling party will not cause localized overheating and coating thermal fatigue performance. use as high temperature oxidation and high temperature corrosion and other coating materials:NiCr, NiAl, MCrAl, MCrAlY(M=Co, Ni, Fe) and Hastiloy and Stellite alloys. Typical applications of such coatings such as power plant boiler four tubes (water wall tubes, reheater tubes, superheater tubes and economizer tubes) and water wall High temperature oxidation corrosion has been a power, paper, chemical and other industrial boilers users need to solve the problem, after years of research, practice has proved that the use of arc spraying Ni -Cr, Fe-Cr-Al, Ni-Cr- Al, 45CT and other coatings can get a good protective effect, the longest life up to 9 years. MCrAlY coatings used in aviation turbine engine blades and a turbine engine combustor coatings, fire extinguishers and other thermal barrier coatings with the underlying bond.

4, thermal barrier coatings

ZrO2, al2O3 other ceramic coatings, high melting point, low thermal conductivity, high temperature conditions on the base metal has good thermal protective effect known as thermal barrier coating. This coating is generally composed of two systems, one for the bottom layer of metal , the other is made of a ceramic surface, sometimes in order to reduce the difference in thermal expansion between the metal and the ceramic coating and to improve the stress distribution, often adding a transition layer between the adhesive primer and a ceramic surface layer, the intermediate layer or by and the underlying metal surface layer of ceramic material mixed in different proportions or multi-layer coating of metal and ceramic materials by continuously changing the coating composition to form a so-called component (or function) gradient coating metal adhesive primer as Co or Ni , added with Cr, al, Y alloy material, the ceramic material is preferably used by the Y2O3 stabilized ZrO2, thermal barrier coatings are generally used for diesel engine piston, turbine engine combustion chamber, valves and the like flame

5 , insulating coating

ceramic materials not only has high hardness and excellent wear resistance, but also has very good insulating properties, the use of high-energy plasma spray coating of Al2O3 dense, high dielectric strength, is the ideal insulation coating. If an organic or inorganic substance coating layer further sealing treatment, will get even better insulation. present this highly insulating polymer material coating films have been used for activating the roll surface corona discharge treatment good effect.

6, the coating gap control

composite powder coating soft abradable seal coating on the substrate is the development of high temperature aerospace industry up quickly seal gap control technology, One important application of modern thermal spray coating. using the contact member with the movement of the abradable coating material powder is mixed powder composed of two or agglomerated powder composition by flame or plasma spraying thereof. Generally, the a metal body and a wear coating nonmetallic filler, the filler is typically graphite, polyester, boron nitride, etc. The role of the filler is reduced integrity of the coating itself, which can enhance the wear resistance of the coating. has developed a series can be worn with a spray coating material, these coatings for surface air sealing parts, between the compressor or turbine blade surface structure or machine and metal gates, get a good seal. abradable coating can also be used in the labyrinth, the coating is used to divert cooling air, the compressed air to reduce the loss of the engine, and maintaining the pressure balance of the rotor shaft.

7, the size of the coating to restore

Thermal spraying is a recovery component size kinds of economic and effective way, whether it is due to work or because of wear and tear caused by machining the workpiece size tolerance undesirable, can be restored using thermal spray technology. This approach is neither welding deformation, nor as a special plating process as expensive while a new surface may be formed of a wear resistant material, or resist, or may be the same as the material constituting the workpiece. repair a variety of shaft and the plunger member is the typical application, including regression shaft, automobile axis, reciprocating piston, journal, rollers, paper dryer and petrochemical industry pump impeller blades and the shell. generator cylinder repair the equatorial plane of the field of thermal spray coating is heat recovery plane workpiece size of a successful application cases. generator cylinder in long-term use of which sub-surface due fretting, corrosion and erosion hot steam flow occurs, such as the role of many different shapes, sizes ranging and varied shades of damage caused by the leak and affect the efficiency of the generator. using thermal spraying methods, respectively destruction at each spraying to fill, and then polished so that the cylinder plane restored to achieve the required level of dimensional accuracy. thermal spray technology may well be the weight of large, complex and expensive on-site repair equatorial plane of the cylinder safety (will not happen deformation), a simple and efficient way.

8, the biological functional coating

sprayed ceramic coating on the biological function of stainless steel or titanium substrate, such as hydroxyapatite, can effectively overcome artificial bones and metal incompatible with living tissue and body fluids corrosion problems and to improve the binding of human tissue and artificial implants.

9, at the far-red radiation coating

some oxides having a high thermal emissivity, When the heat can radiate far infrared waves at this wave energy can easily be organic polymer molecules to produce heat (such as paint), water, air and other substances resonance absorption, thereby speed up the process in the heating element This coating sprayed, its energy-saving efficiency is generally average at 25~40% about

>> Previous: Electricity acceptance criteria

>> Next: Partner