Cooling tower corrosion desulfurization technology

Air pollution is an obstacle for enterprise development. Failed desulfurization project in order to achieve the desired results through the rectification is not possible, because the technology is its congenital defects doomed. Solve the environmental problem is the road extension Shu enterprise development.

XYDS desulphurization and dust removal technology has been once for all construction projects can be successful is because it addresses the following six key technical issues: 1, the device does not corrode. 2, below the emission standards to ensure that the treatment effect. 3 , chimney smoke do not take water. 4, does not clog. 5, does not affect the boiler production. 6, sulfur dioxide is absorbed (SO2) is no longer released, and no secondary pollution.

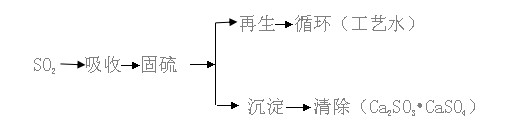

Process

with sodium hydroxide (NaOH) as a base fluid to absorb SO2, with lime (CaO) Sulfur regeneration while NaOH recycling. advantage is: NaOH to absorb SO2 rapid chemical reaction rate is fast, effective, and can be regenerated, wastewater is not discharged. caO be absorbed SO2 Sulfur makes no release of the toxic SO2 gas absorption and generate solid compound innocuous (Gypsum Ca2SO3 •CaSO4↓) all precipitated in water.

bi-alkali process Strong scientific theory is a complete desulfurization technology. Meanwhile, two bases can be used to further denitrification process.

nitrogen oxides (NOx) features like SO2 is soluble in water and is more easily absorbed by alkali solution. NO in the flue gas accounts for 90%, it is for not absorb water or alkali solution must be in order to be transformed after oxidation NaOH solution absorbs addition is absorbed by NaOH, but also absorbed Na2SO3, which fits well with our absorption conditions The bi-alkali process.s sense, to desulfurization, denitrification and removal purposes.

control device

As the governance process produces highly corrosive media, causing serious corrosion damage control equipment, is a direct result of the failure of one of the reasons desulfurization project This technology uses high-quality granite as a material control equipment, with extremely good performance corrosion resistant, etc.

governance structure of the device is designed for full coverage multi-flue gas treatment sequence, repeated dust, repeated absorption (SO2), timely desulfurization, gas-liquid separation, dehydration to fog and into a tower-step treatment. SO2 emission standards soot reaches below after purification exhaust gas temperature ≥60℃.

Ⅲ-type device can simultaneously flue gas NOx, SO2 and dust which three pollutants by a tower-step treatment discharge standards.

Features

— good governance effects

— does not corrode

— smoke without emptying the water

— does not affect the boiler (kiln) combustion

— High Technology (wastewater) regeneration efficiency of

— is not blocked

— long-term stable operation of high-performance and reliable

— long life (the device body more than two decades)

— is no longer absorbed release, not secondary pollution, to achieve the purpose of governance

— convenient operation management

My company developed the HD - LT series coatings, is dedicated cooling tower corrosion, moisture-proof coating which is a modified epoxy resin coating series primer and polyurethane topcoat. primer was modified epoxy resin, fillers, moisture agent, promoting agent components. finish is polyurethane synthetic resin-based material, coloring pigments, curing agents. film after has excellent weathering aging, anti-freeze-thaw, heat, acid, good crack resistance, anti-corrosion, anti-mildew, paint adhesion.

【 Scope 】

1, the power plant cooling towers

2, petroleum, chemical, metallurgy and other industries recycled water, sewage systems, basement waterproofing. equipment also applies to steel and concrete foundation of environmental protection, construction, etc.

【 Features 】

cooling tower corrosion Coatings: has a low viscosity, permeability, permeable to the concrete inside the pores of the concrete characteristics of solid rivet has excellent resistance with impermeable, waterproof, anti-corrosion effect;. coating has good adhesion, abrasion resistance , flexibility, coating with excellent water, alkali, oil, salt and corrosion performance of other media.

coating surface smooth and bright, full, with a sense of enamel abrasion resistance, flexibility, adhesion, insulation resistance, good hardness, higher gloss. chemical properties: corrosion resistance, outdoor durability, weather resistance, etc.

【 use 】

1, the base surface requirements: concrete surface moisture content should be less than 8%, polished concrete surface to remove loose layer of depressions or cracks should be repaired after painting

2, the construction conditions: ambient temperature of 10 ℃-35℃, relative humidity 85% The following;.. when outdoor jobs, rain , snow, wind and other inclement weather, non-painting after

3, coating formulation: before using the component A Stir, add proportionally component B remix Stir aging 15min to construction. Construction thinner viscosity adjustment, the maximum amount not to exceed 10% paint mixed in the applicable period (6 hours) run

4, the drying time is: Tack ≤ 2h;.. pragmatic ≤24h.

5, the construction method: airless spray, air spray, roller and brush.

6, the amount of paint: 40um under conditions of dry film thickness, the theoretical amount of 10.2 m2/ kg. The actual amount will vary due to different factors, such as the coating method, the construction environment, structure and surface to be coated, such as smoothness, usually more than the theoretical amount 30%-80%.

【 Construction Methods 】

Surface Treatment

1, the cement structure surface, need oil, dust, etc. in addition to all surface contaminants, sand blasting or high pressure water gun handling.

2, the steel surface, to be sandblasted to achieve sa 2.5 class or artificial rust or mechanical polishing up st3 level All affected

3, the dislocation, edges and other defects can not paint or paint sanding with power tools.

Spray

1, the pre-painting

2, prior to spraying check for spraying difficult to reach the site, and if so, you need to approach them with a brush painting in advance, to ensure that all concrete surfaces are coated to paint, and generally consistent coating thickness.

3 , spray, roller or brush

airless spray is recommended for construction.

in the wind over two should not be sprayed, but otherwise easily lead to serious waste paint dry spray paint is not a continuous film, coated matte film from the substrate surface. airbrush away to 350~ 450mm appropriate. avoid too close cause cellulite, sagging, too thick or too far causing film is not continuous, coarse, extremely wasteful and paint mist Before construction after the procedure, you should confirm their painting intervals to meet the technical requirements.

【 Notes 】

1, the paint must be in proportion to the provisions of the existing service is used, the use of period runs out.

2, The paint is flammable and must keep away from heat, isolated from sources of ignition. work site smoking is not allowed. construction site should be well ventilated.

3, to prevent contact with skin and eyes paint (use overalls, gloves, goggles, masks and protection of oil), if contact with skin, apply water and soap or a suitable industrial cleaning agent thoroughly cleaned as eye contamination, wash with water more than 10 minutes, and seek immediate medical attention.

4, after brushing finished for 7 - 8 days (at least 5 days) curing time.

>> Previous: Cold Spray Technology

>> Next: Electricity acceptance criteria