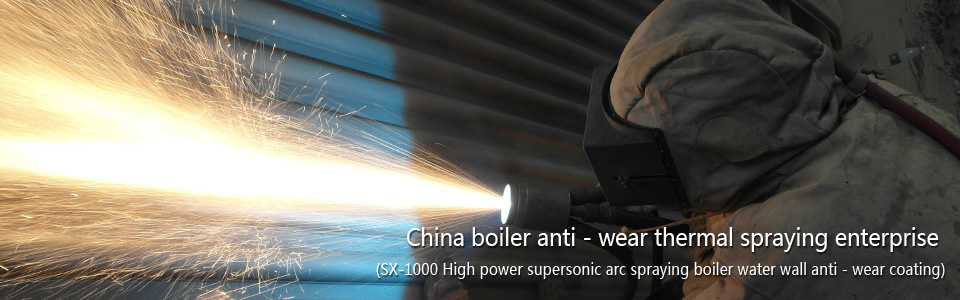

Thermal spray coatings industry application processing series

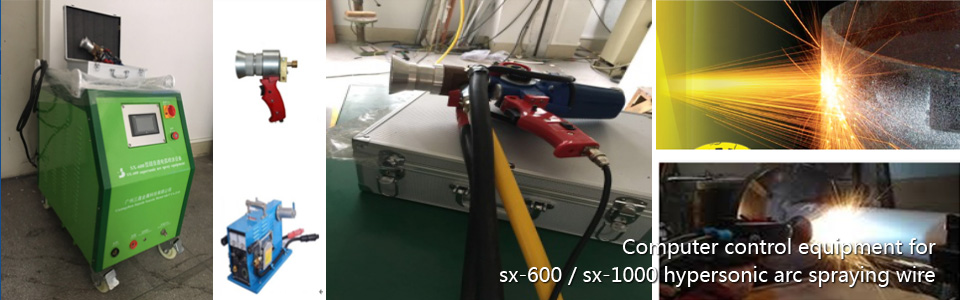

The company has a plasma spray equipment, HVOF equipment, electric arc spraying equipment, wire flame spraying equipment, powder flame spraying equipment, and related coating performance testing equipment, the associated coating processing equipment.

Independent production company can thickness 0.01 mm to ten millimeters, high hardness HRC70, meet the various needs of wear and corrosion (and high temperature), antioxidant, conductivity, insulation, thermal conductivity, such as magnetic metals, ceramic coating, either pre-product protection, but also can make the old new parts to restore performance. thermal spray technology through the treated parts meet or exceed the performance of new parts, manufacturers can save costs and improve economic efficiency.

thermal spray coating processing series

is a series of thermal spraying process, in these processes, finely dispersed metal or non-metallic coating material in a molten or semi-molten state, to one kind of deposition After preparation of the substrate surface to form a coating layer is deposited, which is the use of a heat source (such as arc, plasma or flame spraying, etc.) or filamentary powdered metal or non-metallic material is heated to a molten or semi-molten state, Then leave the flame itself or by a constant speed jet of compressed air to the pretreated substrate surface, having a surface coating formed by deposition of a variety of technical features.

Application IDM

Different parts of the thermal spraying repair

1. paper machine dryer HT20 - 40 surface scratches, corrosion and wear, localized corrosion pits at both ends of the cylinder surface subsidence, the need to repair and strengthen, to prevent further corrosion of stainless steel scrap arc spray formula:1Gr18Ni9Ti

(Features: spraying speed, high bond strength, acid and other corrosive)

2. plastic drum shaft steel mills, iron bearing bit mild abrasion wear tolerance: Fast Nickel Brush Plating

severe wear: press club 45-bit thermal spraying bearing nickel-based powder

3. on mild abrasion wear tolerance: Fast Nickel Brush Plating

4. beater shaft 45 bit worn bearings, shaft surface is worn wear debris mild: Fast Nickel Brush Plating

severe wear: nickel-based thermal spray powder

5. Blanket stick coated with copper bearing bit worn, wear debris shaft surface is worn lightly: Fast Nickel Brush Plating

severe wear: nickel-based thermal spray powder

6. cage bearing steel bearings bit mild abrasion wear tolerance: Fast Nickel Brush Plating

severe wear: nickel-based thermal spray powder

7.ZBJ13/φ 150 pump copper bearing bit mild abrasion wear tolerance: Fast Nickel Brush Plating

8. Pulp copper propeller shaft bore wear tolerance mild wear: Fast Nickel Brush Plating

severe wear: nickel-based thermal spray powder

9.ZBJ2Q1φ 100 fine cast iron pump shaft, shell bearing bit mild abrasion wear tolerance: Fast Nickel Brush Plating

10. steam ball machine steel, iron axes, hole Bearing bit mild abrasion wear tolerance: Fast Nickel Brush Plating

severe wear: with the surface of nickel-based thermal spray powder

11. Daogun Ensilage_Cutters mild steel abrasion wear tolerance: Quick brush plating Ni

12. cyclone machine steel, iron, each bearing bit mild abrasion wear tolerance: Fast Nickel Brush Plating

severe wear: nickel-based thermal spray powder

13. calender each bearing steel bit mild abrasion wear tolerance: Fast Nickel Brush Plating

14. Various motor bearing position, the size of the repair steel cast iron cover each bearing bit mild abrasion wear tolerance: quick brush plating Ni

severe wear: nickel-based thermal spray powder

15. cage axis

cylinder paper machine cage through the long axis of the shaft is a network throughout the cage, bearing wear tolerance ends after can not be used to change the axis or repair welding method can only be scrapped. a cage of about 8 thousand dollars. using brush plating technology can accurately fix the size of the bearing position of the ultra-poor recovery cage of performance, brush plating costs only around $ 200.

Casting

casting, forging equipment work with dust and corrosive environments, corrosion and wear of mechanical parts would be more serious. Xuzhou Heavenly surface technology can repair all kinds of casting machine hydraulic system parts, such as hydraulic rams and other repair renovation, with bits and various parts, such as bearing position, sealing position nine, chemicals, pesticides and machinery because often work with acidic corrosive environment, so repair such machinery, to consider corrosion problems Xinyi Pesticide Factory hydraulic ram Electric Plating site. a ○, the hydraulic pressure system of pumps, piston, valve and other fixes.:① Xuzhou Metalforming Machine Manufacturing Co., Ltd. special hydraulic cylinders Pull ditch repair flawed one, such as flour mills of various types of bearings bearings, rotor, pressing roller; repair of all types of imported sugar with bits of equipment accessories

Paper Machinery

steamer. dryer, oven inner wall zengshou enhanced repair; various rollers class surface strengthening and repair; centrifugal pump, steam boilers, valves and other parts of the mixer shaft gland repair; Corrugated surface hardening (by strengthening treatment, Corrugated surface hardness can be increased to HV1200, Corrugated working life of up to 4000 meters above)

Textile

Rolla, wire hook, rapier loom weft refers wear-resistant coating;. sparse cotton machine pressure roller, small roller, Xilin rolls, cast iron outer disk, roll surface to surface roller shaft, drive shaft on the chopper, Astoria axis; through steam valve sizing machine, drying room flat side of the shaft junction, immersion baskets axis , sizing roller head, spindle journal, guide roller, squeezing roller, roller measuring humidity resurgence, after the shaft journal, fabric yarn journal; grades plus and pull off the perilous roller, large roller (black roll), the whole Seiki Rolla, Rolla guide drivers, hot rolls and rolls of wire, cloth roller, roll surface and journal printing, wire wheels, friction plate (sheet) and other wear-resistant coating.

Printing

printing press India rolls; ceramic anilox; coating roller, ink roller, printing rollers, water roller; dental pad; dental tablets

Metallurgy

blast furnace tuyere, slag notch corrosion resistant coating;. slab even casting mold lines, guide rollers and the conveying rollers; steel and nonferrous metal processing in various process roll; roll steel surface treatment of various class production line (such as a continuous annealing furnace hearth roll, the sink roll, and various galvanized guide roller., tension rollers, etc.) wear, corrosion and other coatings and anti-tumor volume

Power

mill, turbine rotor and generator rotor journal, cylinder joint surface repair; boiler tube wear and corrosion four coatings; turbine blade cavitation and wear-resistant coating; gas turbine blades, flame tube, high temperature resistant protective coating transition section; fan impeller, ball mill wear parts wear-resistant coating; door core, door rods, valve, valve accessories, seat wear and corrosion coatings and boiler repair related equipment parts strengthening

Transportation

Various wear parts wear-resistant coating;. automobile engine base, synchronizer rings, curved roller repair and strengthen the pre- ; gear box housings, cylinder piston, front axle support shaft, the door frame rails, engine main bearing seat, rocker shafts, axle seal bit, wear-resistant coating wear the pin at; dredger rake head, wear rings, mud bucket, twisted blade, shovel teeth, mud pump impeller, shaft ship's stern, stern state copper sets, eccentric bushings, gear shafts, mud pump seal neck, mud doors, skateboards, sand scraper scraping The plate wear-resistant coating, etc.

Chemical

various containers, reactors, pipes, pumps, valves and repair of the seal member; various enamel cans, containers dedicated site repair; boilers, air compressors, pumps other parts repair.

glass industry

by thermal spraying methods to enhance roller, conveyor roller surface layer of ceramic coating to improve the upgrade rolls, the molten glass corrosion resistance conveyor roller, roller surface of molten liquid suppression The adhesion of the molten glass to mitigate erosion of the roller surface, the roller surface remains smooth for a long time, to reduce the lifting rollers, conveyor roller maintenance and improve glass quality and production yield and reduce production costs.

and electrical-line

HVOF process using the pull Sita round, wire drawing machine, drawing wheel, wire wheel, wire drawing cylinders, closing reel, guide grooves and other parts surface coating carbide ceramic coating, the surface hardness of HRc75, than grind chilled cast iron with steel or high abrasion resistance; also the matrix of these parts using ordinary steel or cast iron, both to reduce costs and extend the life of

Municipal

various types of steel thermal spray long. effective protective coatings, anti-corrosion, long-term corrosion, a protective life of up to 30 years

light

Plastic Mold Remediation spray; extruder screw and rubber mixer rotor Spraying; various rollers class Bearing bit spraying repair and strengthening.