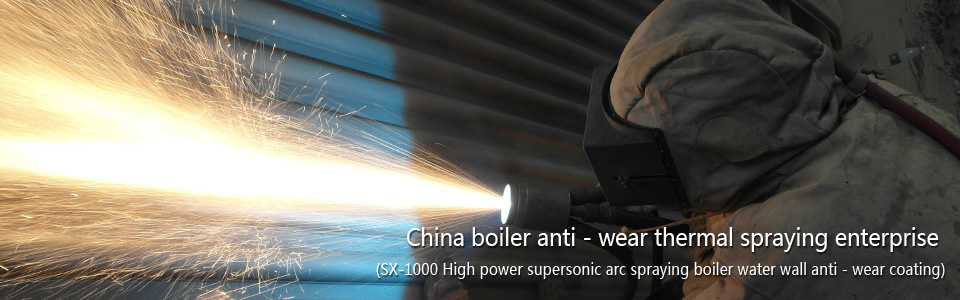

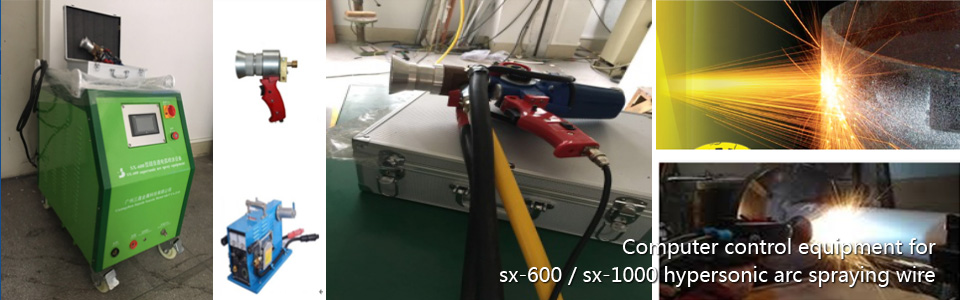

Thermal spray coating applications in the power industry

First, the power system:

1. thermal power plant boiler water wall tubes, superheater tubes, reheater tubes, economizer (or oil) tube, called “ Boiler four ” corrosion resistant coating coatings;

2. thermal power plant steam turbine combination of surface leakage spray head repair;

3. thermal power plant smoke, exhaust fan impeller and mill spray system repair and surface hardening;

4. hydropower turbine parts guide in overcurrent, gates shell, vacuum tube drainage, runner, guide vane ring, housing and other anti-cavitation erosion spray layer;

5. diesel generator crankshaft repair the wear and tear; spray

6. wind power base of the

. Second, metallurgical:

1. repair and strengthening of various rolls;

2. seamless steel pipe manufacturer of composite instead of steel rolling mill roof top spray process manufacturing, life expectancy increased by more than 4 — 5 times;

3. blast furnace slag mouth, outlet original material is molten hot metal poor corrosion resistance of copper, plasma spraying copper +Ni-Cr-AL+Ni/ AL2O3 ceramics and oxides, and increased life expectancy more than doubled;

4. silicon steel continuous annealing line decarbonization, carbon graphite furnace care Limit the use of bottom roller set temperature of 950 ℃, can not be produced at higher temperatures disposable high grade cold rolled silicon steel sheet, using plasma, HVOF, explosion sprayed ceramic and cermet coatings new hearth roll in 920 ℃ over the service life of three months or more, 920 ℃ The following average life of more than six months, the longest reach more than a year, the new roller hearth import substitution, save foreign exchange, create a significant indirect billion economic and social benefits;

5. caster rolls a value of RMB pick up a few million, due to the continuous operation in high temperature, high temperature oxidation and constantly being deformed feet, our Baosteel, Wuhan Iron and Steel and other units of foreign advanced experience, casting automatic submerged arc welding machine rolls, supersonic plasma spraying or flame spraying gas explosion Ni -Cr-AL+ composite ceramic coating repair and strengthening;

6. repair and strengthen the various shafts, crankshafts and other imported cars

III. , non-ferrous industrial systems:

1. nonferrous metallurgy, petrochemical bit more than one thousand tons hydraulic press, hydraulic machines and other large ram extruder using oxyacetylene flame, such as self-fluxing alloy powder spray method, successfully repaired φ850× 5500 ram a Root original 280,000 yuan, is considered to be “ DAVID ” large plunger hundreds of roots, received good economic;

2. copper processing plant all kinds of rolls, aluminum extrusion nozzle carbon electrodes repair

four coal systems:

1. mine shaft equipment sprayed zinc, aluminum, plastic corrosion resistant coating;

2. coal scraper middle groove, piston with alloy wear-resistant coating spray. V. petroleum system

large steel tanks refinery thermal sprayed aluminum coating thickness 100:

1. m, inorganic zinc coating thickness is closed 50 -150μ m, corrosion life of up to 15 years above; -80μ oilfield drill pipe joints using plasma spray tool joints than the original 35CrMo high life more than doubled;

2. various pumps, plunger repair;

3. repair and strengthen various shaft, imported cars the inner surface of the crankshaft, etc.

4. six, chemical industry

Metal Coating:

1. carbonation tower fertilizer plants, gas cabinets, wine storage tanks, beer fermentation tank, distillation towers, various chemical containers sprayed aluminum, zinc, tin, lead, stainless steel and other corrosion-resistant coating and large valve repair;: ceramic coating

2. pharmacy, biochemistry, food, chemical companies within the new system after the reactor surface sand-blasting spray AL2O3, cr2O2, tiO2 other ceramic coating of vitreous enamel coating or replace the reactor partially shedding repair coating;: plastic coating

3. Sports truss structures, utilities, various types of chemical containers, large diameter pipes, ceramic industry Lu mud board surface boxes, printing and dyeing industry, cloth roller, belt conveyor coal industry, iron roller, guide roller presses, such as spraying a variety of anti-friction wear-resistant nylon coating, and spray coating of polyethylene, EVA resin, chlorinated polyether, epoxy resin anticorrosive coating, electrostatic spray to make up for deficiencies.: Seven machinery industry

is a large butterfly valve worth ten thousand dollars a year to consume at least more than 20 oil fields, according to the annual consumption of the top ten major oilfield The valve 200 or more, if you consider the annual consumption of large valves in other industries is even greater, using 1Cr18Ni9Ti material coating repair, you can improve the life of a:

1. 2-fold at 350 ℃ environment, alone in the oil economic sectors receive more than 10 million years; except oil, some valve manufacturers and several large soda investigation, general domestic iron gate 2040 is only 720 hours practical life, far less than the national standard 3000 hours, several major national soda and other chemical industry demand for such large valves tens of thousands of years, because life is mainly the loss is considerable. Practice has proved that the ordinary steel surface coating of nickel-based tungsten carbide coating, its life can increase 3 - 4-fold, if comprehensively promote life by doubling the annual economic benefit tens of millions; - kinds of imported automobile engine crankshaft, crankshaft train locomotives, marine crankshaft, mine air compressor crankshaft, various large rotor shaft, Luoci fan shaft repair;

2. screw conveyor rods, various die-casting, injection molding, rubber molding, glass mold and cold, drawing, forging, hot extrusion, hot, hot red, etc. mold remediation;

3. arc spraying rapid manufacturing molds

4. 电弧喷涂快速制造模具.